SEA

From concept to implementation

Due to many years of work, we have created proven calculation procedures, modern design and verification programs, which now form a technological basis that allows engineers to successfully track progress and solve problems of any complexity formulated by customers. The company has technology and equipment to realize all possible technical and design solutions for transformers

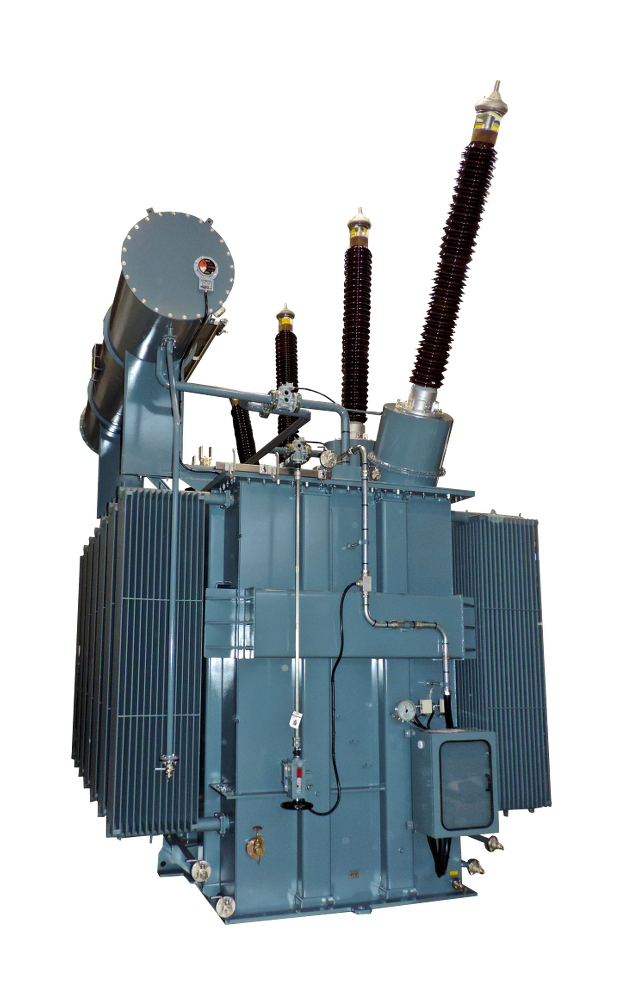

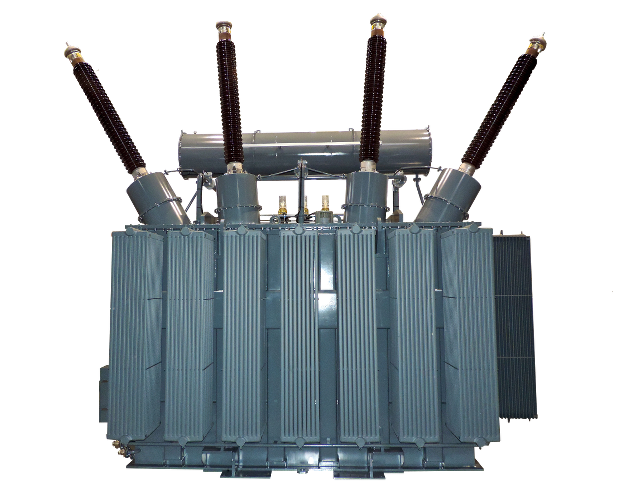

OTN, OTR and OTF series. This diversity allows the optimization of the dimensional range, the right insulation, the resistance to overload or reinforced working cycles for maximum reliability and flexibility that is expected

from the transformer to the customer or the planning company.

OTN, OTR and OTF series. This diversity allows the optimization of the dimensional range, the right insulation, the resistance to overload or reinforced working cycles for maximum reliability and flexibility that is expected

from the transformer to the customer or the planning company.

SEA

Low vibrations, low losses - high performance

the constant search for optimal materials is carried out in order to increase efficiency, reduce vibration and noise of transformers during use. to achieve these goals, the core consists of magnetic textured sheets with high permeability and low specific losses, separated from each other by inorganic insulating inserts. in particular, the cutting and assembly of the core are carried out in such a way that step-lap connections are made to reduce noise, no-load losses and no-load current. the magnet package is with a bent sheet profile and screwed if necessary to further reduce the cost and local heating of the core.

the overall result is a high dimensional accuracy, a low loss and an excellent space filling factor.

in addition, sea can also offer solutions with amorphous metal sheets for very low no-load losses. if the size requires it, axial channels are created in the core to obtain a uniform temperature field.